Pioneers in the pleasure of your palate

Recoveco Garbanzo, a very rich food and the best production in Sinaloa.

Our mission

At Garbanzo RECOVECO we are pleased to report that our product has proven to be successful in the local market and we are excited about the opportunity to offer it to international markets.

Our company, Garbanzo RECOVECO, is committed to producing chickpeas with high quality standards, taking care of their construction so that they preserve their nutrients. Garbanzo RECOVECO has distinguished itself by satisfying the needs and expectations of its target market and providing excellent customer service.

The product

RECOVECO Chickpea is a 100% Mexican grain, which is distinguished by being an extra thick grain, rounded in shape, very wrinkled skin with very marked grooves and a very light color, almost white. RECOVECO Chickpea is ideal for both Mediterranean and Mexican cuisine.

Sinaloa, where our product is proudly harvested, is a leading chickpea producing state in Mexico and an expert in the chickpea industry worldwide and the state from which this Mexican grain is mostly exported due to its rich flavor that has placed this local grain as a favorite. Worldwide.

The optimal temperature required for the germination of quality chickpeas from Garbanzo RECOVECO is in the range of 25 to 35°C, although it may be able to germinate from 10°C.

Technical sheet

RECOVECO Chickpea prefers that its orchards have deeply tilled soils since the root system of the RECOVECO Chickpea plant is very well developed and is very resistant to drought.

The quality of the chickpea is classified according to the size of the grain where caliber 0 refers to a weight of 30 grams and there are 48 to 50 grains; The larger the grain size, the larger the caliber combined with the shape and roughness and the color and tone of the grain's skin.

Exterior

Physical and morphological characteristics:

a) The color of the RECOVECO Garbanzo grain is very light yellowish white.

b) The shape of our grain is elongated and blunt on the sides, presenting irregularities on its surface with deep grooves and bulges.

c) Up to 2% of chickpeas that do not correspond to the characteristics described in point are allowed a and b above, as long as they DO NOT detract from the general appearance.

d) The minimum size accepted within the quality standards for RECOVECO Chickpea is 8 mm, with up to 4% of chickpeas with a lower size being allowed.

e) The weight of 1,000 chickpeas must be at least 490 grams.

Interior

Organoleptic characteristics:

a) Buttery and slightly grainy albumen.

b) Soft and thin skin, attached to the grain.

c) The flavor will always be pleasant, with the absence of foreign flavors.

Recoveco Quality Control

For Garbanzo RECOVECO, chickpea quality control is crucial to guarantee customer satisfaction and meet international standards. Some key aspects of our quality control include:

1. Appearance and size

We verify that the chickpeas meet the specified size and appearance requirements, guaranteeing uniformity in the lot.

2. Purity

We ensure that the batch is free of impurities, such as stones, dirt or other unwanted grains.

3. Humidity

We control the humidity level to prevent storage problems and ensure product durability.

4. Color and shine

We evaluate the color and brightness of the chickpeas, especially important in varieties like Kabuli.

5. Damage and defects

We inspect the chickpeas for cracks, breaks or damage that may affect the quality of the product.

6. Microbiological tests

We carry out tests to guarantee the absence of pathogenic microorganisms that could compromise food safety.

7. Chemical analysis

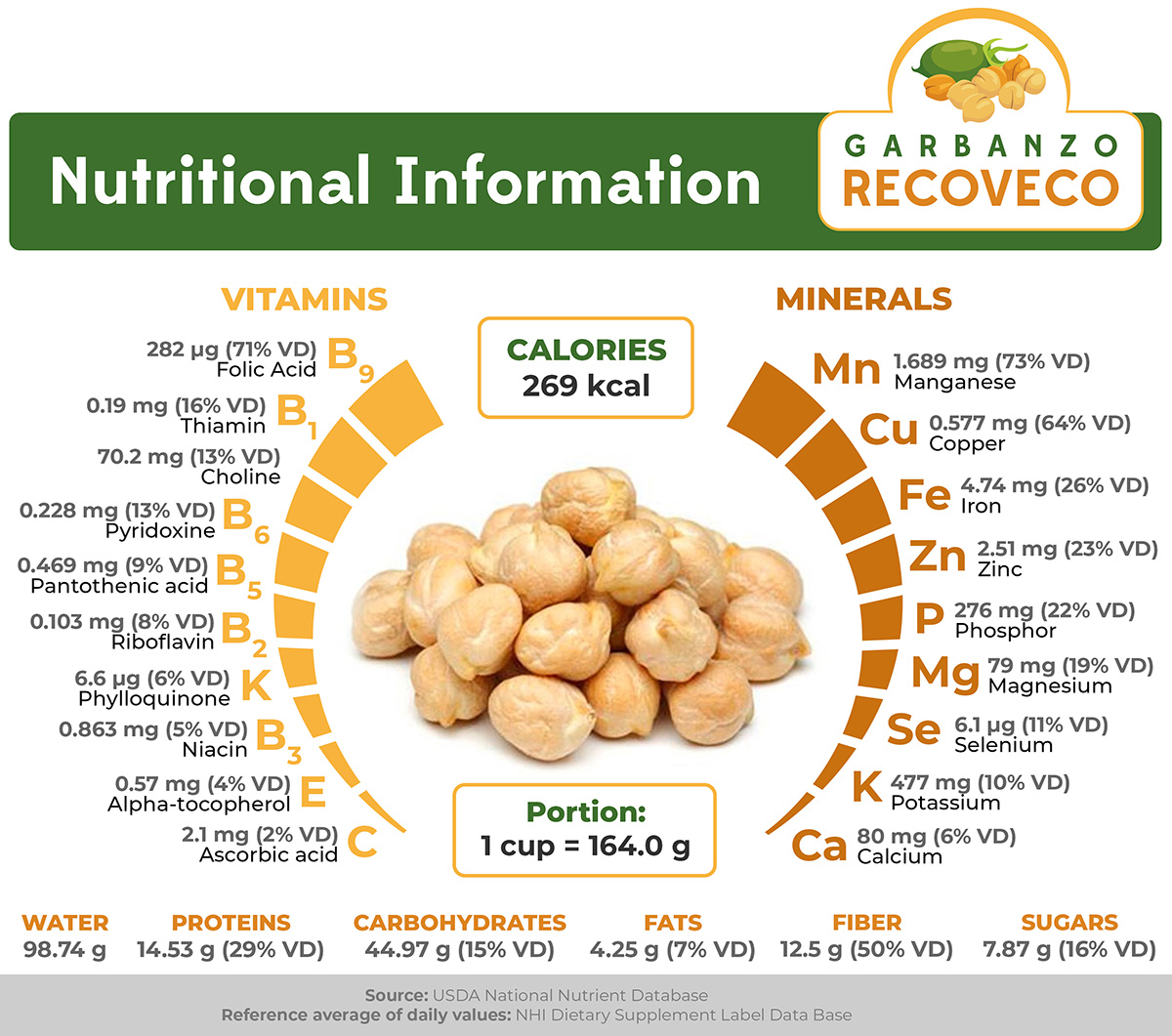

We verify the chemical composition to ensure that the chickpeas meet nutritional and quality standards.

8. Packaging and labeling

(if applicable) We confirm that the packaging is adequate and is correctly labeled with the required information in accordance with the standard and tariff fraction.

For Garbanzo RECOVECO, quality control must be carried out throughout the entire process, where it begins from harvest to export, thus guaranteeing a final product that meets customer expectations and the requirements of the international market.